Thermal Imaging

A picture’s worth a thousand words.

Thermal Imaging is a no contact, non-invasive, non-destructive method to safely assess a truly vast array of equipment.

Saltwater Air & Electrical is now offering accredited Thermal Image Scanning, along with our existing electrical, heating, ventilation and air conditioning services.

As a family owned and operated business, we have invested heavily in this training and technology, knowing its application and value. A picture really is worth a thousand words.

Accredited thermographic reporting is now mandatory with many insurers because of its accuracy and non-negotiable nature.

Equipment

Our choice of infrared thermal imaging technology is FLIR. This is because of its proven High Thermal Resolution, Thermal Sensitivity, Wide Temperature Range and Optics – paramount for quality thermography.

Serious customers understand the need for this level of accuracy and dependability with the thermographic scans.

Experience

As a family-owned and operated business, we have extensive experience across multiple industries both Australia wide and internationally. From agricultural enterprise, through to residential homes, commercial premises, supermarkets and factory, we have gained a respectful appreciation for sound and accurate diagnosis, repairs and maintenance.

As an anchor to our business, thermography enlists the experience and technology we have to augment your preventative maintenance program.

Is a Thermographic Scan Worth it?

As we ply our trade, a significant part of what we do is diagnose and repair multiple types of electrical, mechanical and associated equipment.

This can be very costly for the customer and time consuming for us.

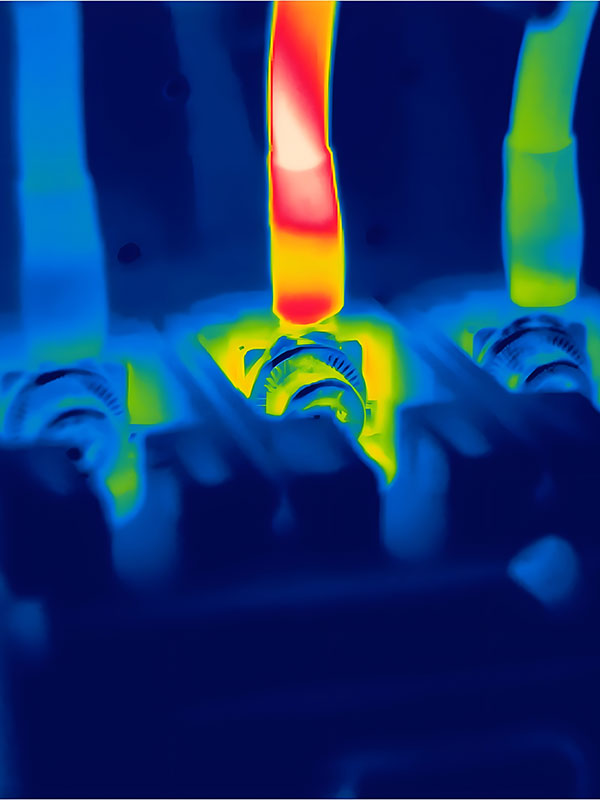

This is where thermal imaging comes in to its own as an infra-red snapshot that highlights differences in temperature, unseen to our naked eye.

In practical terms, this means seeing a picture of what is or isn’t normal and no equipment needs to be dismantled or tampered with in carrying out the assessment.

It is non-invasive and non-contact testing. The images can be used for predictive diagnostic means to take action ahead of time.

Is a Thermographic Scan Expensive?

In the event of a breakdown, what is the opportunity cost of a downed machine? What will the downtime cost? What is the possible cost of a vital component in addition to repair time? And what will the material and labour cost, above and beyond downtime?

For example, switchboard failures can quickly run into thousands of dollars, with hourly rates of $150-$300 plus cost of materials, in addition to downtime costs. There are also very real safety, compliance and nuisance issues.

Conversely, a fault or anomoly picked up ahead of time will cost a fraction of this. Examples include something as simple as tightening a loose screw to avoid a fire starting arc, expensive motor burnout or dangerous shock situation; finding a previously known moisture ingress problem which could’ve caused major damage; or indentifying a compromised battery bank to name a few.

How much does Thermal Imaging Cost?

In general, each site will have its own specific requirements, variables and number of images required which affect pricing and reporting.

Please contact us with any queries you may have.

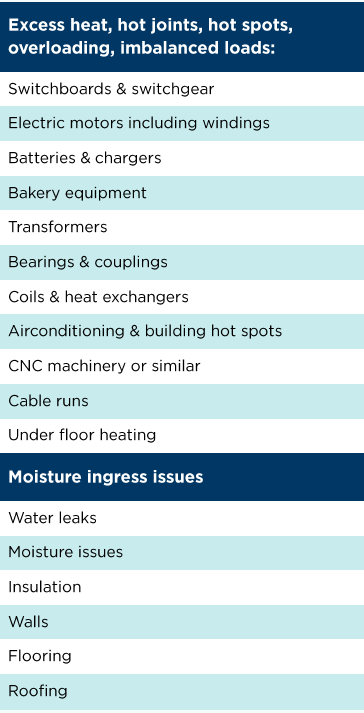

Application – A few examples

Action & Advice

The thermal scan & report we supply is such that it stands on its own merit. It provides necessary technical information for a trained professional to interpret data, as specific to the equipment – this may be a third party.

As fully licensed, dual ticketed, electrical and HVAC electricians, we may be able to carry out corrective action. However, this would be determised on a case by case basis and strictly in accordance with the customer’s policies and procedures, and within the scope of our expertise.